Our Value Proposition

Why Choose Us

The Cooling Companion

Process Cooling Solutions

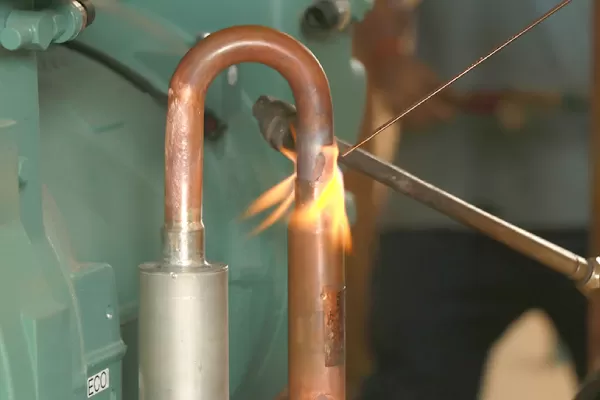

Whether it is the manufacturing of automotive parts, a food processing unit, oil & gas plants or the pharmaceutical industry- demand for the sector is ever-increasing, and an engineering process is involved. As technology advances in Industrial applications, process cooling- also called industrial cooling, plays a central role in maintaining the quality of end products and the integrity of processes. The reason is simple- Chillers are commonly used to remove heat from an operation due to their ability to provide cooling capacity regardless of changes to the application’s ambient temperature, heat load and flow requirements.

Keep in mind that the chillers used in process cooling systems are ‘not’ the same types of equipment as those in the air conditioning market, though the terminologies sound similar. Industrial chillers take the principles behind a home air conditioning system to the next level. From the manufacture of dairy products to the preservation of food to the development of lifesaving processes & medicines, what all have in common is using a unit to cool water or air to chill equipment or a particular area. To find a balance between supply and sustainability, energy efficiencies are crucial when it comes to minimising costs, and systems need to be of high quality to keep performance reliable.

Tempcon, a leading name in the process cooling industry, ensures maximum quality and cleanliness of the cooling fluid, resulting in improved process efficiency and productivity as well as reduced power consumption & maintenance costs. We are a trusted partner, working alongside our clients to enable technology breakthroughs that improve the world.

Market Penetration

98%

Sales & Service

92%

Technological Advancement

95%

The Tempcon Promise

For manufacturing companies, factors such as safety, efficiency and reliability all affect the quality of a product and ultimately influence overall customer satisfaction. Measuring quality in numerous ways at each phase of a product’s lifecycle plays a pivotal role—from initial concept, design, installation, testing, commissioning, operation, maintenance, decommissioning and eventual disposal.

Quality is in Tempcon’s DNA, and our manufacturing facilities are ISO 9001 compliant. Optimum quality, corrosion resistance, safe & areliable range of Process Cooling equipment is our top priority. Best quality practices right from selection of components, during installation and during performance testing. Multiple stages of verification assure quality and, thus, performance. Our competent and trained team of engineers ensures we adhere to standard quality protocol, providing top-notch customer service that will make your experience even more enjoyable. We are working with some renowned companies hailing from different industries like pharma, plastic, food, medical and chemical.

To ensure that our clients are not faced with any hassle regarding functionality, we provide them with repair, engineering and maintenance services for chilling plants. Along with manufacturing, we believe in educating, guiding & safeguarding our customers. Our industrial process cooling products can be tailored to meet exact requirements to ensure maximum energy efficiency whilst minimising operational costs.